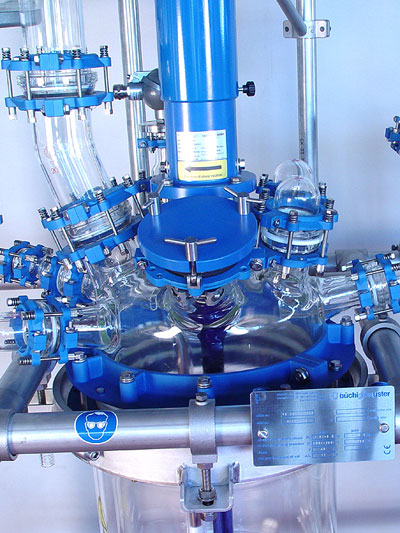

Glass reactor: 15, 30, 60 liter

Pressure: -1.0 (FV) to +0.5 bar

Temperature: -60 °C (-90°C) to +200 °C

Material: Borosilicate glass 3.3 / glass lined steel / PTFE / PFA / Tantalum

• Other setups are available.

Basic glass pilot reactor and pilot plant

Performance and reliability are key issues in the explosion proof design of Buchi glass reaction systems. The inert materials allow safe processing in an inert atmosphere of a wide range of solvents and acids in a completely sealed glass reaction system under full vacuum. Multiple chemical reaction steps are performed safely in the same setup.

The system consists of:

Reactor, solid jacketed full view glass reactor to easily improve and control chemical reactions by visual observation.

Distillation glass overhead built with buchiflex components (unique flexible ball - socket joints) for multiple, reliable processes under full vacuum.

The BR/GR type chemReactor is a basic pilot reactor system for chemical process development, scale-up, process simulation and kilo-scale cGMP production in batch and semi-batch operation.

We produce complete solutions for chemical processing: Reactor systems including accessories like sampling devices, pH probes, rectification columns with structured packing, process monitoring and control as well as integration of auxiliary equipment such as temperature control units, nutsch filters / dryers, scrubbers or mixing vessels.

Standard package

• Jacketed full glass reactor

• Multipurpose glass distillation overhead

• Stainless steel frame, supporting flexible glass superstructure

• ATEX Zone 1 (0) / CE / cGMP

• CIP capable

• FDA conform, highly corrosion resistant

• Complete documentation

Standard options

• chemReactor CR type Distillation glass overhead

• Reactor lift for easy opening (vessel cleaning)

• Triple wall reactor vessel

• Sampling device

• pH monitoring and control

• Gas introduction (Nitrogen purging and active gas)

• Vacuum / exhaust piping

• Additional feeders / receivers

• Solid feeding

• IQ / OQ / PQ

Reactor vessel

Reactor vessel• Jacketed glass reactor 15, 30, 60 liter

• Baffle with Pt100 temperature sensor

• Flush mounted drain valve (zero dead volume)

Glass dome / Glass lined cover plate

Glass dome / Glass lined cover plate• Glass cover dome (15, 30, 60 liter)

• Glass lined steel cover (60 liter)

• Fast-action closure for addition of solids

• 8 connection nozzles

ATEX stirrer drive

ATEX stirrer drive• ATEX stirrer drive (motor and adjustable transmission)

• ATEX dry running mechanical seal

• Glass lined steel impeller stirrer

Distillation glass overhead

Distillation glass overhead• Feed vessel for liquid addition

• Distillation column / vapor duct with pressure gauge and bursting disc

• Spiral condenser with vacuum / exhaust connection

• Receiver vessel for collection of distillate

• Self-draining «buchiflex» glass piping

• for GR type glass-overhead: see chemReactor CR

Typical applications

• Vacuum distillation

• Azeotropic distillation (phase separation)

• Evaporation to any desired consistency

• Multi-component chemical reactions

• Gas introduction into liquid phase

• Chemical synthesis

• Extraction of multi phase mixture

• Crystallization

• Refluxing

• Multiple chemical reactions liquid/liquid, liquid/solid

• Low temperature chemistry